A result of the new COVID-19 situations in the past two years, masks have become more popular all over the world. In addition to medical masks, luminous masks made of optical fiber fabrics have also emerged, which combine technology and fashion.

Below you will find a description of how luminous optical fiber masks are made:

1. Getting the tools ready- to make the luminous optical fiber mask, we need the following equipment: scissors, hot melt gun, hot cutter, hot hair dryer, sewing machine, high temperature marker, ruler, and heat shrink tube.

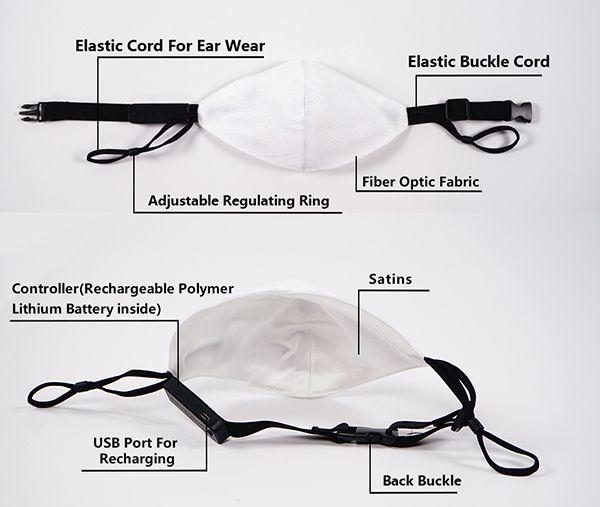

2. Preparation of raw materials- the raw materials include half a meter of fiber optic cloth, a breathing valve, half a meter of nano anti-virus fabric, half a meter of three-in-one non-woven fabric, one meter of ear straps, two adjustment buttons, one USB charging cable and one drive regulator.

3. Using a high-temperature marker, draw the dimensions and specifications for the outlet cover on white paper and cut it out. A mask has two pieces, a left piece and a right piece. Nano anti-virus fabric and three-in-one non-woven fabric have anti-virus properties.

Using the two cut-out templates, place the fiber cloth and nano anti-virus fabric on the three-in-one non-woven fabric, and draw the two slides on the left and right side of the outlet cover and after that, cut 6 pieces out with scissors.

You need to pay attention to the fiber fabric here. Fiber fabric cannot be cut as it guides the light.

4. The next step involves sewing the optical fiber fabrics and nano anti-virus fabrics together.

A support cloth is made of the nano anti-virus fabric, and the support is attached to the two pieces of fiber cloth that are sewn together, and the other pieces of nonwoven fabric are stitched together.

One of them is sewn with a pocket on the back so that the light source controller can be installed. The pocket measures 2*5 CM when sewn with the back of the fiber optic fabric. Add a nose bridge and add lanyards to the ears and you’re done.

5. During this step, the optical fiber bundle and electronic part are coupled: first the optical fiber is bundled, and then the fiber port is trimmed with a heat cutter.

The coupling buckle and heat shrink tube are attached to the electronic controller, with the light source screwed in, then the mask is turned over and sealed with a sewing machine.

6. Open a breathing valve round the mouth using a laser machine or knife mold, then insert the breathing valve. A breathing valve is made up of an outer cover, a filter element, and an inner cover.

The outer part is positioned outside the fiber fabric, and the filter element is positioned from the inside of the mask. Install the breathing valve by putting it in the outer cover, then pressing the outer cover on top of the inner cover.

Using the threads, make a circle around the mask, attach the adjustment buckles to the ear ropes, and then test the luminous effect of the mask, and the whole mask is ready.

Masks made from luminescent fibers have both anti-virus and luminescence properties. Moreover, they are safe, fashionable, can be washed repeatedly, and can be worn repeatedly. Therefore, people who love fashion and beauty find it very appealing.

This is an excellent example of fiber optic fabrics used in clothing. These masks are effective against viruses and have a protection effect of 96%.

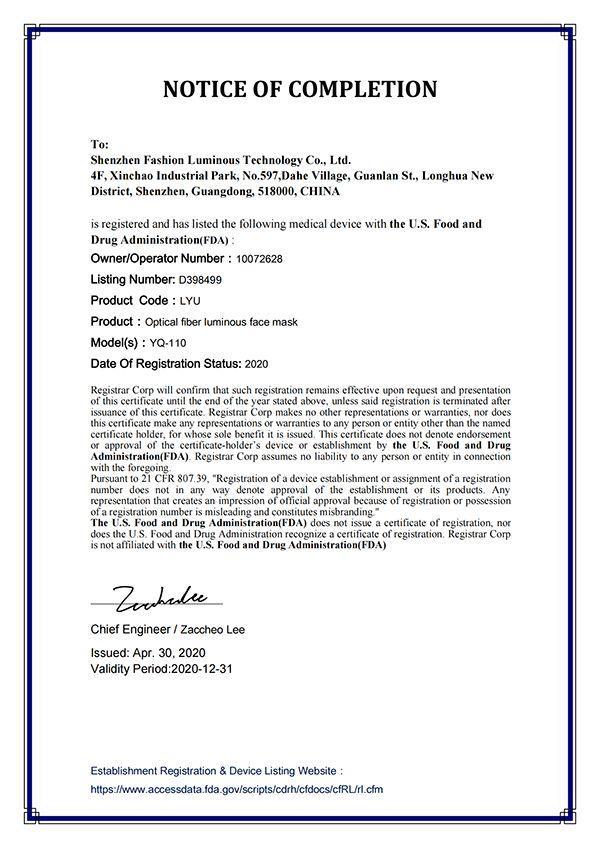

Here is a copy of the FDA inspection certificate:

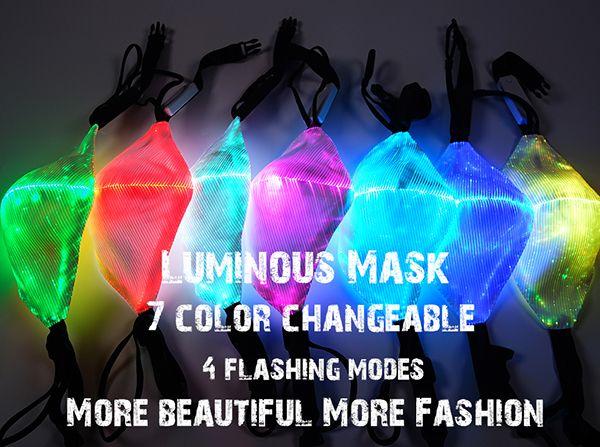

These masks can emit light and change color at the same time and feature red, green, blue, orange, purple, yellow, pink, and seven other colors.

Changeable modes include gradual color changes, fast color changes, flashing and jumping. In addition to protecting people from viruses, it gives them the enjoyment of technology and beauty. People really like it.

As a result, people wear masks in a more conscious way, enjoying a better life. In addition, you can also make optical fiber masks with various shapes and patterns according to your personal interests.

The premise of my introduction above is that it should be an easy, meaningful and joyful experience. A video will accompany this article so that everyone can easily learn about the topic.